The design parameters and a step-by-step procedure of designing a string are given in API RP 7G 16th ed Section 7. Stiffness ratio bending strength ratio.

Drill String Design Calculations Complete Guide Drilling Manual

Up to 10 cash back Web Design Graphic Design Illustration Design Tools User Experience Design Game Design 3D Animation Fashion Design Architectural Design Interior Design Other Design.

. The drillstring design is completed from first principles and using spreadsheets so that. The courses are very interactive making them a. Drill string design process is placed in context with other planning and operational considerations of well planning.

Transmit and support torsional loads. This will give a good understanding in interpreting the outputs of torque and drag software. The participants will learn about the drill pipe grade the limitation for torque and tension and the drill collars tensional stress.

Participants will learn about the mechanical properties of all drillstring components including their connections both as individual pieces and when made up into a drillstring. See below for further details on course content and duration. Drill string handling and.

Transmit and support axial loads. Drilling Efficiency Optimisation DEO Stuck Pipe Prevention. It is seamless with threaded connections.

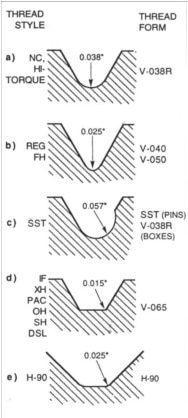

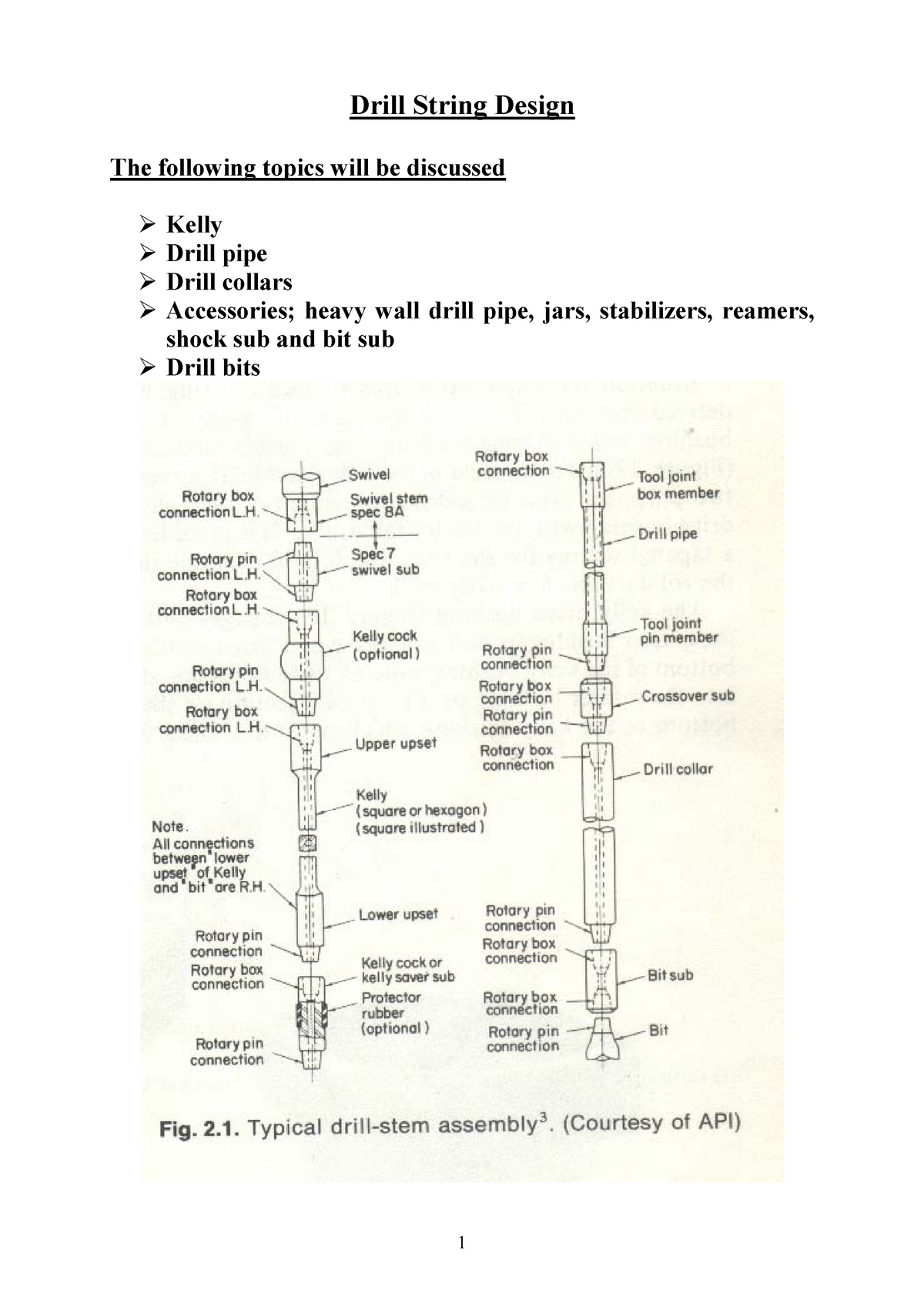

The drill pipe has two tool joints one female is called a box and the other male is called pin. It is easy to be done just remember dont exceed 80 of drill pipes yield strength. The concept of drill-string design is well understood.

The ROP optimization and the factors that influence the ROP are discussed and the existing ROP models are explained. Who this course is for. The Drill String Design Manual has been produced to assist engineers in the selection design and placement of the appropriate components within a drill string.

To provide engineer with solid grounding in well hydraulics. Torque drag and casing wear mitigation. Course About the Course We have been presenting Drill String Design workshops for over 12 years for all types of operations around the world.

To provide a solid ground in drillstring selection and design and diagnosis of failures. This allows components to be specified such that the applied load remains below the rated load with some reserve capacity built in for use in an emergency. The course provides a comprehensive treatment of drill string design as well as the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as the standard DS1 for design and inspection.

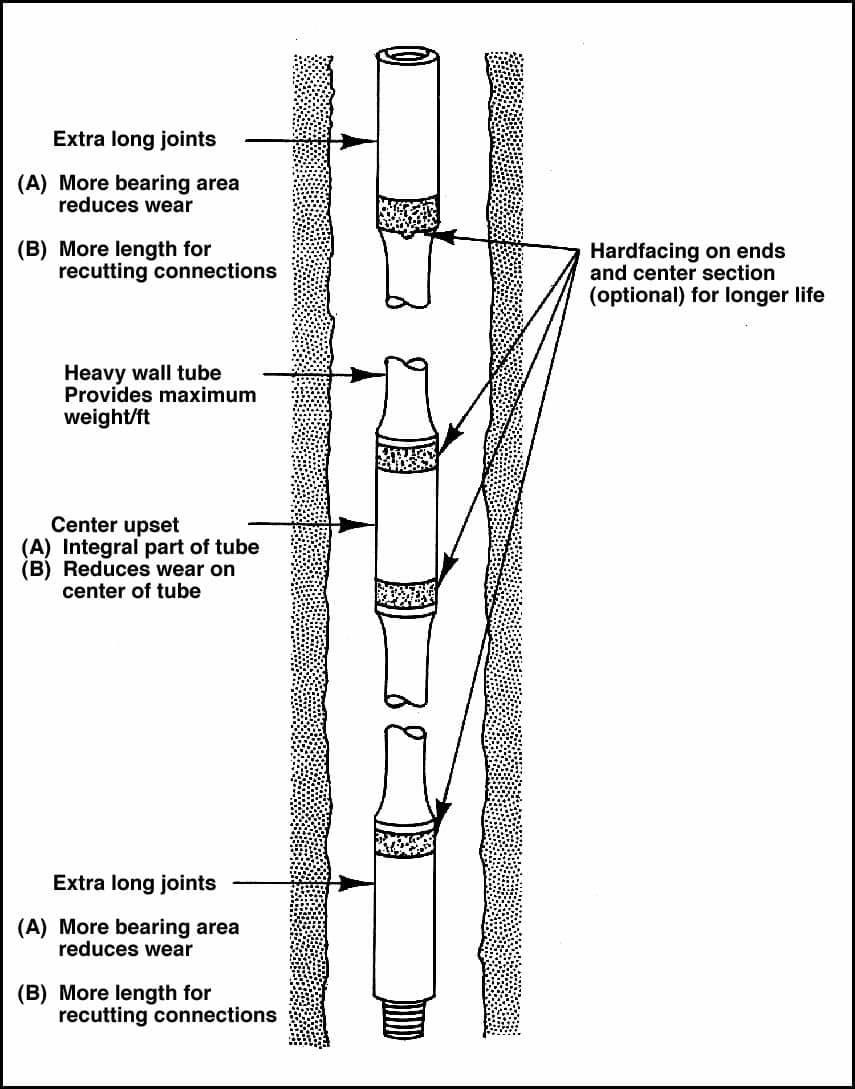

The fundamental pendulum assembly increases the restoring force by increasing the pendulum length with a stabiliser in the proper position. The course provides a comprehensive treatment of drill string design as well as the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as an overview of. Identifies the chemical and mechanical environments and conditions that can shorten the life of drill string components.

Diagnose and mitigate vibration to reduce drill string damage and failure. Slip Crushing Slips exert hoop compression on the drill pipe which can deform the pipe if conditions are unfavorable. When the drillstring is lowered into the borehole the total length of the drillstring is under tension due to its own weight which is partly counterbalanced by the buoyancy.

Torque and tensile loads can be modelled accurately for a range of load cases that are expected within the given well operation using torque and drag software. Optimize your drill string inspection program using the latest industry standards. The drill pipe constitutes the majority of the drill string length.

Drillstring Design and Drilling Optimization with Mud Motor Operation. It clarifies the performance properties of drill string components and explains how to apply design margins. Written by specialist drilling engineers it will assist in your drill string design for a particular well.

The course provides a comprehensive treatment of drill string design practices with theoretical underpinnings. A basic overview of what design is and how the drill crew can contribute to its effectiveness ie. Drill string design needs from you to check the maximum over pull you can apply to drill string without drill pipes failure.

Using both vertical and directional well profiles participants are taken through the design of a drillstring for various scenarios using current design standards. Learn the basics of drillstring mechanics theoretical background Acquire deep understanding about drillstring mechanics applications for complex drilling such as Torque Drag Buckling Fatigue and casing wear Quick start. Taking into consideration the environment and the stresses and strains that the drill string will be required to operate under.

Drill string with 800 t drill collars Solution f1 4212800 5265 cs f2 2662800 23275 cs N1 20 x 5265 105 rpm N2 20 x 23275 67 rpm Then drill pipe must be rotated below 67 rpm or greater than 105 rpm The two method shows great variation String vibration can be reduced by changing the natural. 4-Drill string components مكونات خيط الحفر knowledge of string components New Rating. All our courses can be conducted via video conferencing or in person at a location of your choosing.

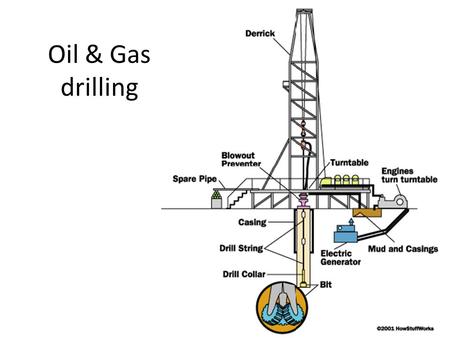

The course is intended to provide drilling and well engineers with the competency to design a drillstring for a well. Topics covered include vertical and deviated well string design selection of BHA to provide the required WOB. The drill string is required to serve three basic functions.

Drill string and BHA failure prevention. This is a three day course designed to take Engineers up to the level where they can confidently perform a hand calculation based design of a drill string. Contact us for prices and schedules.

This drilling string design program is a unique course discussing all factors that influence the drill string during operations. It refreshes hidden physics of drill string failures and mechanical properties of drill string materials. Various operational loads and limits discussed will provide more comprehensive view of the drillstring mechanics.

Vibration monitoring and avoidance. Another recommended source document is G. Subsurface Consultants Associates LLC Training Webinars Drillstring Design and Drilling Optimization with Mud Motor Operation.

BHA design concepts are investigated with emphasis on practical engineer. This 5-day course will address all elements of drillstring selection and design integrating drilling optimisation with drillstring failure prevention. The different types of drill bit and their applications are outlined in detail.

Drilling Engineering Software Application Competency Matrices. Drillstring and BHA Functions of drill pipe drillcollars grades of drill pipe and strength properties thread types tool joints. The outer diameter of the tool joint is larger than the body of the drill pipe to accommodate the threads.

This course will cover the basic drillstring and bottom-hole assembly BHA design including drill bit. We are constantly updating our materials to reflect the latest technology applications for both near-vertical and high-angle well designs while maintaining a thorough grounding in the fundamentals.

Basics Of Drill String Design Skillsupload

Bottom Hole Assembly Bha Components And Design Drilling Manual

Drill String Design Calculations Complete Guide Drilling Manual

Basic Drilling School Course Objectives During This Drilling School You Will Get All The Knowledge About Drilling Oil And Gas Wells Design Requirements Ppt Download

0 comments

Post a Comment